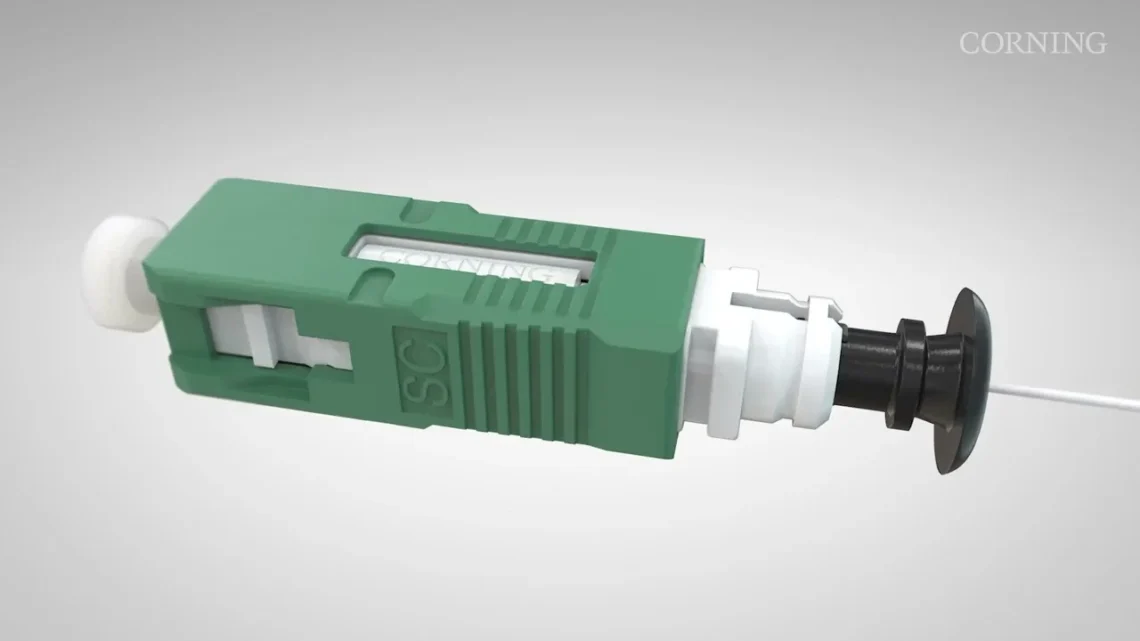

1. What are No Polish Connectors (NPC)?

A No Polish Connector (often abbreviated NPC) is a type of field-installable fiber optic connector designed to eliminate the need for polishing the fiber end face on site. Traditional fiber optic connectors usually require the field technician to apply epoxy or adhesive to fix the fiber into a ferrule, then polish the end surface to achieve proper optical quality. NPCs simplify this by using a factory-polished ferrule or fiber stub, which is built into the connector. The installer then only needs to cleave the field fiber, insert it, and use a mechanical splice or clamp mechanism.

Some common NPC systems use these features:

- A mechanical splice: aligning the cleaved field fiber with the factory polished stub, without polishing.

- Pre-assembled, factory polished ferrules/fibre stubs that are built into the connector.

- A strain relief / clamping system to hold the fiber, to avoid loose parts or adhesives in the field

So effectively, no on-site polishing or curing of adhesives is required, which saves time, reduces skill burden, and reduces risk of poor terminations due to polishing errors.

2. How No Polish Connectors Work – Key Components & Installation Process

Understanding how NPCs function helps understand their advantages and where they are best used.

Key components:

- Factory-polished ferrule or fibre stub: Already polished before the connector is shipped; this ensures consistent quality.

- Mechanical splice or clamp: To align and secure the cleaved fiber to the stub. Uses mechanisms like clamps, buffer clamps, splice actuators.

- Boot / jacket holder: Provides strain relief and secures the cable jacket; helps in handling the buffer, jacket, and avoiding bending beyond minimum radius.

- Cleaving tool: To cleave the field fiber (make a flat cut) cleanly; this is crucial since polishing is not done on site. The flat or angle cleave must be precise.

Typical installation steps:

- Prepare the fiber: Strip the buffer and jacket, clean, and cleave the fiber flat (or angle if needed).

- Open or set the connector’s mechanical splice/clamp: The connector is opened or its splice mechanism made ready.

- Insert the cleaved fiber: Align with the factory stub or ferrule inside connector. Ensure alignment, no misplacement.

- Activate the splice/clamp / buffer clamp: Some NPCs have buffer clamps that secure the fiber buffer/jacket, and close or actuate the splice to permanently hold the fiber.

- Boot or strain relief finalization: Slide the boot over and ensure mechanical protection, proper bending radius

The whole process can often be completed in a few minutes (sometimes less than five), especially by trained technicians.

3. Key Benefits of Using No Polish Connector

NPCs are increasingly popular because of several strong advantages:

- Speed of installation: Since there is no epoxy curing or polishing, the connector can be terminated much faster in the field. This reduces labor time and cost.

- Reduced skill requirement: Polishing fiber connectors well requires skill, experience, and good tools. NPCs simplify this so less experienced technicians can still get good quality terminations.

- Consistency and reliability: Factory-polished ferrules/stubs tend to have more consistent geometry and polish quality than field polishing, which can vary greatly. This improves insertion loss, return loss, fewer defects.

- Fewer tools & consumables needed: No polishing films, pads, epoxy, or expensive polishing machines; only cleavers, possibly mechanical tools already in the connector kit.

- Lower field error rate: Because polishing is one of the trickiest steps (cleanliness, angle, finish), removing the polishing step reduces chances of error. Similarly, adhesives can complicate things.

- Better for difficult environments: For installations in remote or harsh areas where carrying polishing tools or maintaining them is difficult, NPCs are more suitable. Also in data centers where speed and minimized downtime matter.

4. Limitations / Challenges of No Polish Connector

NPCs are not perfect for every use case. Here are some limitations and challenges to be aware of:

Performance ceiling: While many NPCs offer excellent performance (low insertion loss, good return loss), in some very high precision applications, polished connectors (with ultra-polish or angle polish) or fusion splicing may still achieve superior metrics. For example, extremely low return loss demands may still favor APC or polished solutions.

Dependence on cleave quality: Because polishing is removed, the flatness and precision of the cleave become more critical. A poor cleave will degrade performance. Handling and cleaning become more important.

Mechanical/splice tolerance: The alignment between the field fiber and factory stub must be very accurate. Misalignment, dirt, debris, or improper actuation of the splice mechanism can cause losses or reflections.

Cost per connector: NPCs may cost more per unit than basic epoxy/polish connectors, though when factoring in labor and tool savings, total cost may still be lower.

Limited re-termination options: Some NPCs are one-time use, or don’t handle re-polishing or re-epoxy; if something goes wrong, you often must discard or replace the connector.

Environmental or long-term degradation concerns: If the mechanical parts (buddy clamps, boots, buffer clamps) are exposed to extreme moisture, dust, temperature changes, performance may suffer. Also, if the factory stub is damaged, the whole connector may need replacement.

Not always accepted in all standards / certifications: Some installations (especially for telecom or regulated infrastructure) may have specifications that require certain polish types or return loss levels, which some NPCs may or may not meet. Always check project specs.

5. Applications & Use Cases

NPCs are especially useful in contexts where speed, field conditions, or cost-efficiency are major considerations. Key use cases include:

- Fiber-to-the-Home (FTTH) / Fiber-to-Premises (FTTP): In deployments where many connectors need to be installed in field with minimal infrastructure. NPCs reduce time

- Enterprise Networks: For patching, adding links inside buildings or across floors, where polished connectors aren’t feasible or efficient on site.

- Data Centers: Quick turnaround installations, expansions, or emergency fixes.

- Outside Plant (OSP): Deployments in remote, harsh or mobile environments (e.g. poles, towers, trailers) where carrying polishing equipment is hard.

- Temporary or Provisional Installations: Situations where permanent polish is less critical, or connectors may need to be removed or replaced.

- Telecommunications / Private Networks: Where standards allow, to speed up provisioning. Some NPCs support both single-mode (SM) and multimode (MM) fibres, standard connector styles like LC, SC, SC APC/UPC etc.

6. Tips for Choosing & Using No Polish Connector Effectively

To maximize the benefits and avoid pitfalls, here are practical tips when selecting or using NPCs:

Check the return loss / insertion loss specifications: Make sure the NPC you pick meets your project’s required levels. If you need high precision or low reflection (e.g. in single-mode, or APC style), verify those specs.

Understand the connector style and compatibility: LC vs SC, APC vs UPC/PC, fiber type (single-mode, OM3, OM4 multimode), and buffer/jacket sizes (250 µm, 900 µm, 1.6-3 mm etc.) must match your cable and network installation. NPCs come in various styles.

Use a proper cleaver and ensure clean cleave: Since polishing is omitted, cleaving quality is crucial. The cleave must be clean, at the correct length, flat (or angle where required). Any debris can degrade optical performance.

Cleanliness is vital: Dirt, dust, or contaminants on cleaved fiber or factory stub degrade performance. Always clean with isopropyl alcohol and lint-free wipes; keep caps/dust covers intact until last moment.

Follow manufacturer’s mechanical splice/clamp actuation instructions: The action that secures the fiber must be done correctly; too little force or mis-alignment will result in higher insertion loss or unstable connection. Test if possible (e.g. with light source & power meter).

Verify environmental specs: If the connector will be used outdoors, or subject to vibration, temperature swings, moisture, check that the NPC is rated for those conditions.

Consider long-term maintenance: If connectors may need replacement or re-termination, factor that into design. Even though NPCs are simpler, sometimes having standardized spare parts, tool kits, cleaver replacement blades improve lifetime.

Training / practice: Even though NPCs reduce complexity, technicians should still practice with sample connectors to understand common pitfalls (e.g. fiber not fully inserted, dust, poor cleaves).

Conclusion

No Polish Connector (NPCs) represent a significant innovation in field fiber optic terminations, offering major advantages in speed, labor savings, and consistency by eliminating the on-site polishing and adhesive curing steps. They are particularly useful for FTTH, enterprise, data center, and outside plant installations where time, simplicity, and reliability are critical.

However, they have trade-offs: performance depends strongly on cleave quality and mechanical alignment, and they may not always satisfy very stringent specifications in certain telecom or scientific applications. For best results, one should carefully choose NPCs that meet necessary specs, use the proper tools, follow clean processes, and ensure the environment and installation conditions are supportive.

If you’re planning to use NPCs, make a checklist (fiber type, connector style, environmental ratings, tools, cleaver quality) and test a sample before full deployment. That way you get the benefit without surprises.