shelves Woodworking is one of the most satisfying and practical projects you can take on—whether you’re building simple storage in a workshop, elegant built‐ins in a living room, or floating wall shelves that seem to hover. In this comprehensive guide, we’ll walk you through everything you need to know: planning, material selection, joinery, mounting, finishing, and more. Read on and by the end you’ll feel confident customizing your own shelf build.

1. Why Build Your Own Shelves Woodworking Style?

There’s a big difference between buying ready-made shelving and committing to shelving built by you with care and craftsmanship. When you choose shelves woodworking, you gain:

-

Customization: You control the dimensions, style, wood species, finish and placement.

-

Durability: Proper joinery and material selection mean your shelf system will outlast many store-bought units.

-

Aesthetic value: A well-finished wooden shelf adds warmth and character to the space, especially compared with cheap metal or particle-board alternatives.

-

Skill growth: Building shelves is a great way to sharpen woodworking skills—measuring, cutting, joinery, mounting and finishing.

-

Sense of accomplishment: There’s something deeply satisfying about seeing a row of books, prized objects or tools neatly arranged on a shelf you crafted yourself.

And because shelving covers so many use-cases—from storage in the garage to display in the living room—this type of woodworking project offers huge versatility.

That said, woodworking shelves also comes with responsibilities: you must design for strength, plan for the load, select appropriate materials, and finish for longevity. Mistakes in these areas can lead to sagging shelves, unstable mounts or unfinished aesthetics. That’s why we’ll walk through each step deeply.

2. Planning Your Shelves Woodworking Project

2.1 Define Purpose & Location

Start by asking: What will these shelves hold? Where will they sit? The answers determine size, material and mount type. For example:

-

Heavy items (paint cans, tools) need deep shelves, strong supports and robust materials.

-

Display items (books, decor) allow shallower depths but call for clean appearance and finishing.

-

Floating shelves create a minimalist look but require hidden strong support.

2.2 Measure & Span Considerations

How long and deep your shelf will be influences how it’s supported. According to woodworking experts, choosing dimensions carefully avoids sag or failure. Key rules:

-

Select shelf depth based on the largest item you’ll store.

-

The span (distance between supports) matters: longer spans require thicker boards, stiffening or more supports.

-

For example: one guideline: “the eye will notice deflection of 1/32 in per running foot” when loaded.

2.3 Choose Adjustable vs Fixed

Decide if you want adjustability (shelf pins, adjustable brackets) or fixed shelves (cut to space).

-

Adjustable gives flexibility for years of changing use.

-

Fixed often cheaper, faster, and more rigid.

WOOD Magazine’s guide lists many options: shelf pins, adjustable standards, fixed dadoes.

2.4 Sketch & Material List

Create a simple drawing. Mark thickness, widths, bracket/cleat locations, joinery. List every board, fastener, bracket, etc.

Planning ahead prevents unnecessary mistakes.

2.5 Mounting & Wall Considerations

-

If wall-mounted, find studs or solid anchor points; drywall alone won’t suffice for heavy loads.

-

Determine bracket type (cleats, metal brackets, hidden floating support).

-

Consider wall finish, outlet access, wiring or other obstructions. The Spruce article on span and spacing gives excellent mounting guidelines.

3. Materials & Wood Selection for Shelves Woodworking

3.1 Wood Type & Thickness

The choice of material dramatically affects performance and cost. Some options:

-

Solid hardwoods (oak, maple, walnut) – strong, beautiful grain, excellent for visible shelving; more expensive.

-

Softwoods/plywood – more affordable, still acceptable for many uses.

-

Plywood/MDF/particle-board – economical, especially for painted shelves; but thinner versions can sag under heavy load.

Woodwork Center’s DIY guide notes that plywood is a popular strong choice, and that pre-drilling is often required.

3.2 Board Thickness & Supports

To avoid sag, you must select a board thick enough (or add reinforcement) for the span and load. For example: Boards supported only at ends need heavier section, or thinner board with lip/edge or backing. The WOOD magazine guide shows how edging or thicker front can reduce sag by half.

3.3 Front Edging & Appearance

When using plywood, adding a solid wood front edge improves both strength and aesthetics. WOOD guide: “Solid wood glued onto full length of shelf’s front edge adds a great deal of strength… also essential for appearance when you use plywood.”

3.4 Hardware & Brackets

Selecting the right support hardware is crucial. Options include: shelf pins (adjustable), metal bracket arms, cleats (wood or metal), floating shelf brackets. Make sure the rating of bracket matches your projected load.

Better Homes & Gardens guide shows proper method to hang floating shelves.

3.5 Joinery & Construction Methods

For fixed shelves or built-ins: use dados, rabbets, biscuits, or dowels for strength. The dado joint is common to seat shelf ends into sides for rigidity.

3.6 Finishing & Sealing

Finish protects wood and defines appearance. Decide on stain, paint, clear coat, or natural finish. Ensure finish suits environment (humidor? bathroom?). The Woodwork Advisor article emphasizes finishing and maintenance.

4. Building Techniques for Shelves Woodworking

4.1 Cutting & Layout

Measure twice, cut once. Ensure boards are square, surfaces clean. For custom shelving: cut sides, top, bottom, shelves first. Use table saw or track saw for straight cuts.

From Instructables bookcase build: “Cut the boards for the bookcase… a table saw will provide the safest and most accurate cuts.”

4.2 Joinery and Assembly

-

Use glue + screws or more refined joinery (dowels, biscuits). For visible shelving units you may prefer clean joints.

-

If building built-in shelving, you might cut dados into sides to insert shelf ends. WOOD guide covers this in detail.

4.3 Mounting to Wall / Installing Brackets

-

Use stud finder, mark stud locations.

-

Install cleats or brackets; ensure level and spaced appropriately.

-

For floating shelves, install hidden bracket, slide shelf on, secure underside screws. Better Homes & Gardens method the same.

-

The Spruce article reminds that span and separation matter.

4.4 Reinforcing, Avoiding Sag

For longer shelves or heavy loads:

-

Use thicker boards or support in middle.

-

Use edge banding or front lip to reduce deflection. WOOD guide: added edging reduced sag by half.

-

Consider adding vertical support under shelf, especially for wide spans. Real-world reddit users recommend mid-supports for long spans.

4.5 Finishing the Shelf

After build: sand to smooth, apply stain or paint, then finish coat (polyurethane, oil, wax). Consider rounding front edge for safety and visual appeal. The Woodwork Advisor article suggests stain/wipe finish and protective topcoat.

5. Types of Shelves Woodworking: Styles and Ideas

5.1 Floating Wall Shelves

These shelves appear to have no visible brackets—clean and modern. But installation requires hidden hardware, strong wall anchor and careful finishing. WOOD magazine has a plan for floating wall shelves.

5.2 Fixed Built-In Shelves / Bookcases

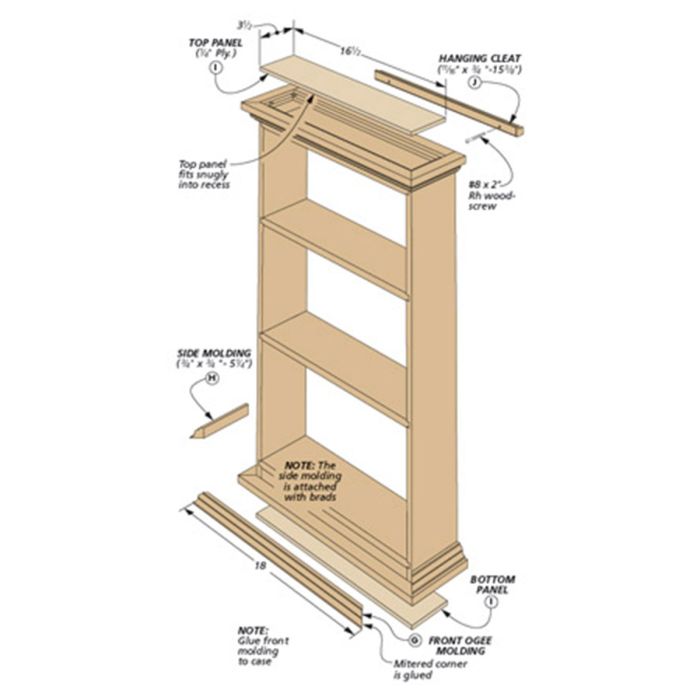

Traditional built-in shelving units anchored to walls, often with side panels, back panels and fixed shelf heights. Durable and elegant. WOOD magazine’s “Shelves for Show” is an example.

5.3 Adjustable Shelves

Shelves where height can be changed via shelf pins or adjustable standards. Very versatile. Wikipedia article on adjustable shelving explains.

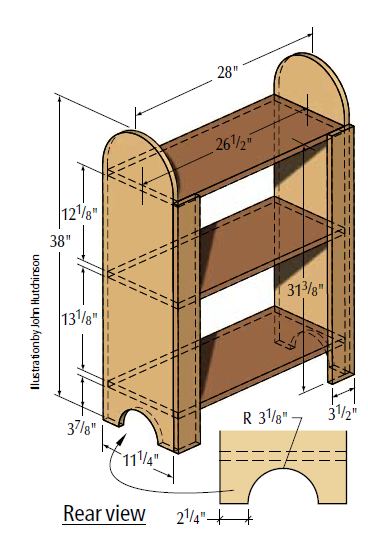

5.4 Stackable / Modular Shelves

Modules that can be stacked vertically or arranged laterally. Great for flexible storage. The Minwax beginner project shows stackable shelves.

5.5 Tool / Workshop Shelves

Heavy‐duty shelving designed for garage or workshop storage of heavy tools, lumber or hardware. Example: tool storage shelves plan.

5.6 Specialty Shelves

Corner shelves, floating hexagon shelves, narrow display ledges—many creative woodworking shelves ideas. Pinterest boards reflect many inspirations.

6. Mounting & Installation Best Practices

6.1 Finding Studs & Anchors

For wall‐mounted shelves, always locate studs or use strong anchors. Studs spaced 16-24” apart typical. The Spruce article outlines material span and support.

6.2 Leveling and Spacing

Use a level for straight installation. For multiple shelves, measure equal vertical spacing. Clear shelf height determined by objects you store.

6.3 Shelf Span & Support Spacing

The longer a shelf span without support, the greater the sag risk. Use brackets or support mid‐span if shelf is wide. Reddit woodworking users frequently discuss this.

6.4 Secure Brackets and Hidden Supports

In floating shelves especially:

-

Drill pilot holes into studs.

-

Secure braces tightly.

-

Slide shelf onto bracket then screw underside to prevent sliding. Better Homes & Gardens gives a clear step by step.

6.5 Final Stabilization & Load Testing

Before adding heavy items:

-

Check for sway.

-

Place increasing weights gradually.

-

Tighten screws after first week (wood may settle).

-

Avoid placing heavy loads far out on a shelf edge without support.

7. Finishing, Maintenance & Longevity

7.1 Finishing Techniques

-

Staining: Enhances grain and color—apply evenly, wipe off excess.

-

Clear Finish: Polyurethane, lacquer or oils protect the wood surface.

-

Paint: For sleek look or matching décor—ensure good primer.

Woodwork Advisor gives finishing advice for wood wall shelves.

7.2 Maintenance

-

Dust regularly.

-

Avoid soaking wood with water—wipe damp, then dry.

-

Tighten loose screws and brackets annually.

-

Monitor sagging over time, especially if load changes.

-

For painted shelves: touch-up chips as soon as they occur to protect underlayer.

7.3 Avoiding Problems

Common issues and fixes:

-

Sagging mid-span → add central support, reduce span, increase thickness.

-

Warping → choose stable wood, acclimate boards to room humidity, allow expansion.

-

Finish peeling → ensure proper surface prep and use high‐quality finish.

-

Mount failure → ensure brackets anchored in studs or use proper drywall anchors rated for load.

8. Common Mistakes in Shelves Woodworking & How to Avoid Them

Mistake #1: Under-estimating the load or span

If you use thin boards for long spans to hold heavy items, you’ll face sag or failure. The Spruce article warns of span/spacing risks.

Fix: Choose thicker wood, add supports or reduce span.

Mistake #2: Mounting only to drywall

Drywall anchors alone might fail under significant weight.

Fix: Always anchor to studs or use heavy‐duty anchor/plate system rated appropriately.

Mistake #3: Poor finish prep

Untreated or poorly sealed wood will chip, stain and wear quickly.

Fix: Sand well, remove dust, apply suitable finish.

Mistake #4: Mis-measuring and cutting

A small error in width or square will show up dramatically.

Fix: Measure twice, clamp and test fit before final glue. The Instructables build stresses accuracy.

Mistake #5: Ignoring fail-safe support

Even aesthetic shelf designs need enough structure. Reddit woodworkers warn about long spans without center support.

Fix: Add central support for spans beyond ~3 feet, or use thicker material.

9. Advanced Tips & Creative Ideas for Shelves Woodworking

-

Hidden hardware / floating look: Use concealed brackets for minimalist look.

-

Mixed materials: Combine wood with metal brackets, glass shelf tops or leather accents.

-

Live edge shelving: Use live edge boards for dramatic, natural look.

-

Integrated lighting: LED strips beneath shelf or inside built‐in units create ambience.

-

Custom joinery: Use dovetail or through‐tenon joinery for visible craft detail.

-

Modular units: Build stackable shelving modules that adapt to changing space. The Minwax beginner project explores stackables.

-

Corner shelving / sloped ceilings: Use templates and angled cuts for tricky spaces. Reddit users discuss this challenge.

10. Cost, Time & Tools Breakdown for Typical Shelves Woodworking Projects

Time

-

Simple wall shelf: a couple of hours (cut, sand, finish, mount).

-

Built-in bookcase: several days (cutting, joinery, assembly, finishing).

-

Floating shelf system wall-wide: several sessions (measurement, bracket install, checking for level, finish, mount).

Cost

Depends heavily on wood species, hardware and finishing.

-

Budget materials (plywood + brackets): low cost.

-

Premium hardwood + custom finish + heavy duty hardware: higher cost.

Make sure to budget for finishing materials and possible extra support hardware if load high.

Tools

Essential tools include: measuring tape, level, stud finder, drill/driver, table or track saw (optional but helpful), clamps, sander, finishing supplies.

More advanced joinery requires router, biscuit joiner, dado set, etc. The Woodwork Center article outlines tool needs.

Conclusion

Shelves woodworking is a rewarding craft that blends utility, design and personal satisfaction. Whether you’re building a basic wall shelf or a full built-in system, giving attention to planning, materials, construction and finishing makes all the difference. Keep in mind:

-

Match shelf design to intended use.

-

Respect span, load and support requirements.

-

Choose material and finish wisely.

-

Install accurately and securely.

By following these principles, your wooden shelves will not only perform well today—they’ll stand the test of time. So grab your saw, measure carefully, and build something you’ll be proud of.

FAQs

1. How deep should a shelf be for general storage?

Depth depends on what you store. For books/display: ~10-12″ is common. For tools/larger items: 16″ or more may be needed. Always measure your items first.

2. What thickness of board should I use for a 4′ span?

For typical solid wood board under moderate load, ¾″ may suffice for ~30–36″ spans. For 4′ plus heavy items, consider 1″ thick board or support every ~18–24″. See span guidelines.

3. Can I use MDF or particle-board for shelving?

Yes, for lighter loads and painted finishes MDF/particle can work. But they sag faster under heavy load or wide spans. The Spruce article suggests caution.

4. How do I install floating wood shelves safely?

Locate studs, install hidden bracket firmly, slide shelf on, then secure from underside with screws to prevent slipping. Level and test before loading.

5. What finish should I use to protect wooden shelves?

Depends on look and use. Clear polyurethane gives durable protection. Oil finishes bring out natural grain. Painted finishes require good primer and top coat. The Woodwork Advisor article covers finishing.