1. Introduction to Softline Tuck Assembly

Softline Tuck Assembly Instruyctions: The Softline Tuck Assembly is a modular furniture or fixture assembly system designed for quick and efficient installation. Whether you’re setting up office panels, partitions, or seating systems, Softline’s innovative design ensures a clean finish with minimal visible fasteners.

The term “Tuck Assembly” refers to how different components are tucked, aligned, and locked together using Softline’s proprietary connectors. These systems are widely used in commercial interiors, modular offices, and architectural installations for their sleek look and easy assembly process.

2. Tools and Materials Needed

Before starting your Softline Tuck Assembly, make sure you have the following tools and components ready:

Tools:

-

Allen wrench set (commonly 4mm or 5mm)

-

Phillips screwdriver

-

Rubber mallet

-

Level

-

Tape measure

Materials:

-

Softline panels or profiles

-

Corner connectors or joiners

-

End caps and trim covers

-

Fastening screws and clips

Having all these materials on hand will make the installation smoother and help you avoid unnecessary delays.

3. Step-by-Step Softline Tuck Assembly Instructions

Follow these step-by-step Softline assembly instructions for a precise and secure setup:

Step 1: Prepare the Work Area

Clear your workspace and lay out all the Softline components. Ensure the floor is flat and clean to avoid alignment issues.

Step 2: Identify Components

Each Softline profile or panel is labeled with a part code. Check the assembly diagram or instruction sheet provided by the manufacturer to confirm where each piece goes.

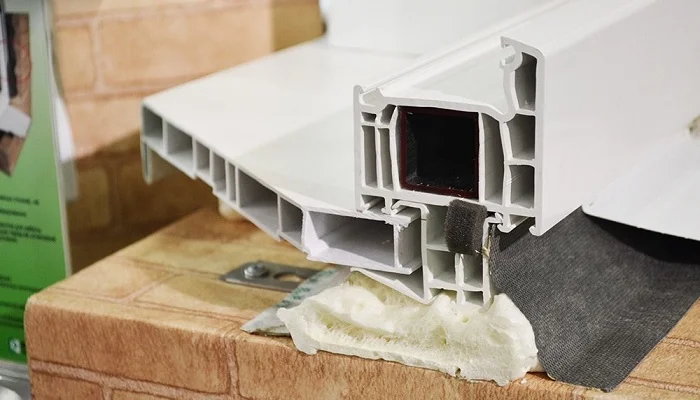

Step 3: Connect the Base Profiles

Start with the bottom Softline track or base profile. Align it on the floor and use a level to ensure it’s perfectly horizontal.

Step 4: Install Vertical Supports

Attach the vertical Softline extrusions into the base track. Gently tap them with a rubber mallet to ensure a snug fit. Secure them with corner brackets or locking clips as per the kit’s design.

Step 5: Add Panels or Inserts

Slide or “tuck” the panels, glass, or fabric inserts between the profiles. The “tuck” mechanism allows for easy fitting without visible screws, giving a seamless finish.

Step 6: Install Top Cap and Trim

Once the panels are in place, fit the top track or cap profile and secure it with screws or locking tabs. Snap on end caps and trim covers to hide any exposed joints.

Step 7: Final Alignment Check

Ensure all panels are aligned properly, tighten all connectors, and make any necessary adjustments before completing the setup.

4. Common Mistakes to Avoid

Even with clear Softline Tuck Assembly Instructions, some users make small errors that can affect the final result. Avoid these common mistakes:

-

Skipping alignment checks – Always level the base and sides before tightening.

-

Using incorrect screws or tools – Only use the fasteners provided in your Softline kit.

-

Forcing components – If a panel doesn’t fit, recheck orientation instead of forcing it.

-

Ignoring part labels – Softline systems are modular, so placement accuracy is key.

Taking a few extra minutes to double-check your setup ensures a professional, long-lasting installation.

5. Maintenance and Care Tips

After assembling your Softline system, it’s essential to keep it clean and in good condition:

-

Wipe surfaces with a soft microfiber cloth.

-

Avoid using abrasive cleaners that can scratch aluminum or laminate finishes.

-

Tighten connectors every few months to prevent loosening due to vibrations.

-

For fabric or glass panels, use suitable cleaners as recommended by the manufacturer.

Routine maintenance ensures your Softline installation remains stable, attractive, and durable for years.

6. Troubleshooting and Support

If you encounter issues during your Softline Tuck Assembly, try these troubleshooting steps:

-

Panels won’t fit: Check for obstructions or reversed orientation.

-

Uneven alignment: Relevel the base track before securing vertical supports.

-

Loose fittings: Make sure all locking clips and screws are fully tightened.

-

Missing parts: Contact the Softline distributor or manufacturer for replacement components.

For complex installations, Softline often provides assembly videos, PDF manuals, or customer service support through their official website or supplier portal.

Conclusion

The Softline Tuck Assembly system combines ease of installation, modern aesthetics, and durability, making it an excellent choice for modular interiors. By following these step-by-step instructions and best practices, you can achieve a clean, secure, and professional-looking installation.

Whether used in offices, retail spaces, or residential projects, Softline’s tuck system offers both functionality and style with minimal effort.

FAQs

1. What does “Tuck Assembly” mean in Softline systems?

It refers to the tuck-and-lock design that allows panels to fit securely without visible screws.

2. Can one person assemble a Softline system?

Yes, smaller setups can be assembled by one person, but large installations may require assistance.

3. What materials can be used with Softline profiles?

Softline supports glass, aluminum, MDF, and fabric panels.

4. Are Softline components reusable?

Yes, they can be disassembled and reinstalled without damaging the profiles.

5. Where can I get official Softline assembly manuals?

They are available on the Softline Systems official website or through authorized dealers.